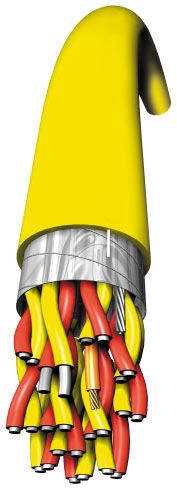

PVC Thermocouple Extension Cable

Overall Shield

PVC twisted/overall shielded thermocouple cable is ideal for systems sensitive to induced voltage and electrical noise. The twisting of the conductor and the Aluminum/polyester taper shield provides protection against cross talk, static and magnetic noise in instrumentation circuits. Conductors are insulated with color-coded PVC, then twisted with a tin/copper drain wire. Next, an Aluminum Mylar tape is wrapped around the wires, followed by a final layer of overall PVC jacket. The wire is UL listed for Power Limited Tray Cable (PLTC) 300V applications and meets NEC Article 725 Class I, Division 2, hazardous locations and NEC 725 for use in Class and Class 3 Circuits.

-

- New Plant Constructions

- Utilities and Industrial Plants

- Petrochemical Plants

- Testing Rig set up

- Thermocouple Circuits

- For use in NEC Article 725 Class 1 Division 2 Hazardous Locations

- Complies with NEC 725 for use in Class 2 and Class 3 Circuits

-

- Metal Overbraid

- Sunlight Resistant

- Passes IEEE 383 Flame Test

- Passes VW-1 Flame Test

- CPE and TPE Constructions are also available

- Special Color Codes

- Available in thermocouple and special limits extension grade

-

- Continuous use up to 221F (105C)

- Flame Retardant

- Excellent Dielectric Strength

- Good Moisture, Chemical and Solvent Resistance

- 100% Continuous Drain/Shield Contact

- Economical Construction

-

Conductors: Solid or stranded thermocouple wire per ASTM E230 & ANSI MC96.1

Insulation: Nominal .016″ (.40mm) flame retardant PVC

Construction: Twisted pairs

Communication Wire (Optional): 22AWG (.61mm) 7-strand copper insulated with nominal .015″ (.38mm) orange PVC ( used in constructions 4 pair and larger)

Cable Shield: .002″(.05mm) aluminum/polyester tape, 25% overlap

Cable Drain Wire: 7-strand tinned copper, 2 AWG sizes smaller than conductor

Outer Jacket: Flame retardant extruded PVC with nylon ripcord under jacket

Operating Temperature: -15F (-26C) t0 +221F (+105C) continuous

Limits of Error: Conforms to ASTM E230, IEC 584 and ANSI MC 96.1

Color Code: Conforms to ASTM E230 and ANSI MC96.1 (International Color Codes Available)

-

UP/ALPTWK – [( 1 )] – [( 2 )] [( 3 )] – [( 4 )]

1) # of Pairs

From 2 to 50 pair (contact for larger pair counts)

2) Wire Size AWG

Available from 16 to 20AWG

3) Add (F) for Stranded Wire

Example: 20F = 20 AWG 7-Strand Conductor

4) Calibration Grade Designation

Type K, N, E, J, T available in Extension Grade*, Special Limits Extensions Grade available upon request

*Extension Grade wire is designated with an X at the end of the thermocouple type. (Example: Extension Grade type K = KX)

UP/ALPTWK – [( 1 )] – [( 2 )] [( 3 )] – [( 4 )]

1) # of Pairs

From 2 to 50 pair (contact for larger pair counts)

2) Wire Size AWG

Available from 16 to 20AWG

3) Add (F) for Stranded Wire

Example: 20F = 20 AWG 7-Strand Conductor

4) Calibration Grade Designation

Type K, N, E, J, T available in Extension Grade*, Special Limits Extensions Grade available upon request

*Extension Grade wire is designated with an X at the end of the thermocouple type. (Example: Extension Grade type K = KX)